Project information

- Hydraulics Motors: Orbital Motors

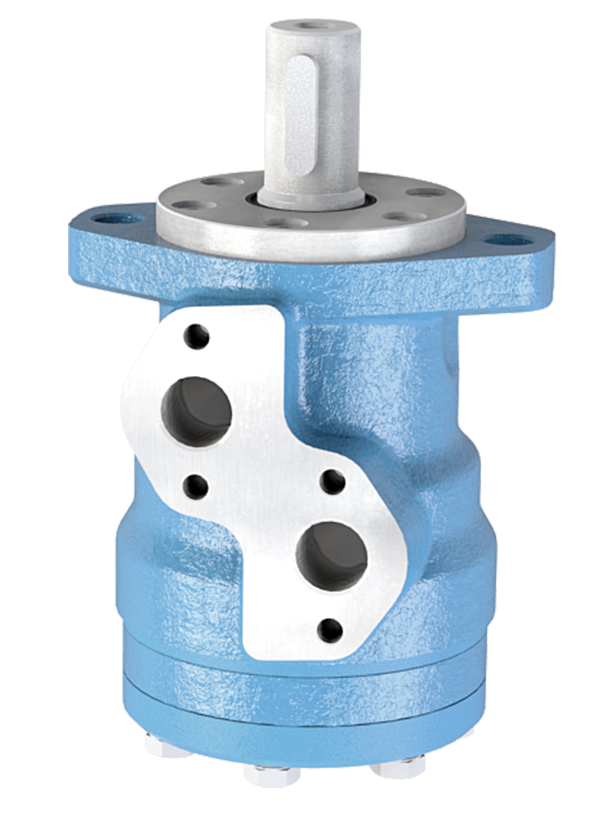

- Model: MGR

- Product Type: LSHT Light Duty

- Product Catalog: Download Catalog

Light Duty Orbital Motor MGR

Orbit motors convert hydraulic energy (pressure, oil flow) into mechanical energy (torque, speed). Hydraulic orbit motors operate on the principle of an internal gear (rotor) rotating within a fixed external gear (stator). The internal gear transmits the torque generated by the application of pressure from hydraulic oil fed into motor which is then delivered via the motor's output shaft. Orbit motors have high starting torque and constant output torque at wide speed range

- Application: Conveyors

Feeding mechanism of robots and manipulators

Metal working machines

Ventilators

Construction plant equipment and access platforms etc.

- Option: Model - Spool valve, gerotor

With or without flange

Side and rear ports

Series with pressure valve(s)

Shafts - straight and splined

Metric and BSPP ports

Speed sensoring

Other special features

| Code |

Displacement [cm3/rev] |

Max. speed [RPM] |

Max. Torgue [daNm] |

Max. Output [kW] |

Max. Pressure Drop [bar] |

Max. Oil Flow [Ipm] |

|||||

| cont. | int* | cont. | int* | cont. | int* | cont. | int* | cont. | int* | ||

| MR 50 | 51,5 | 775 | 970 | 10 | 13 | 7 | 8,5 | 140 | 175 | 40 | 50 |

| MR 80 | 80,3 | 750 | 940 | 20 | 22 | 12,5 | 15 | 175 | 200 | 60 | 75 |

| MR 100 | 99,8 | 600 | 750 | 24 | 28 | 13 | 15 | 175 | 200 | 60 | 75 |

| MR 125 | 125,7 | 475 | 600 | 30 | 34 | 12,5 | 14,5 | 175 | 200 | 60 | 75 |

| MR 160 | 159,6 | 375 | 470 | 39 | 43 | 11,5 | 14 | 175 | 200 | 60 | 75 |

| MR 200 | 199,8 | 300 | 375 | 38,5 | 46 | 9 | 12 | 140 | 175 | 60 | 75 |

| MR 250 | 250,1 | 240 | 300 | 39 | 47 | 8 | 9,5 | 110 | 140 | 60 | 75 |

| MR 315 | 315,7 | 190 | 240 | 36 | 47 | 5 | 8 | 85 | 115 | 60 | 75 |

| MR 400 | 397 | 150 | 190 | 38 | 47 | 4,8 | 6,8 | 65 | 90 | 60 | 75 |

* Intermitten operation: the permissible values may occur for max. 10% of every minute.

General:| Pressure fluid | Mineral based- HLP(DIN 51524) or HM(ISO 6743/4) | |

| Temperature range, | °C | -40÷140 |

| Optimal Viscosity range, | mm2/s | 20÷75 |

| Filtration | ISO code 20/16 (Min. recommended fluid filtration of 25 micron ) |